Biochar cone kilns

Now you can cost effectively make your own quality biochar.

Our locally made Japanese style cone kilns are available here with the backing of our years of knowledge of the kiln process and use of the stable carbon product.

We manufacture a convenient heavy duty flat pack “The Pyrolizer” designed to lower the freight cost around Australia and to New Zealand.

Clean burn technique suited to an Australian context

Making this efficient and effective time saving system not only easy and cheap to accomplish, but put in a format that’s usable and essential for Australian bush blocks and suburban settings alike.

Rethink wasteful burn offs

Improve your soil’s carbon storage, cation exchange, water and nutrient holding, drainage and microbial capacity.

The process

A typical cone is about a 185 litre holding capacity, They are constructed of sturdy stainless steel capable of successive burns over many years. The kiln cones have stainless steel handles and are light enough for one person to transport through a bush block. The earth contact area is about 30cm.

The time taken to do a complete burn and water drench is about 60-90 minutes. The size and amount of dry refuse required is approximately a full/ high trailer load of sticks and limb wood ranging from 4mm bracken, spent raspberry canes, dry cuttings through to 100mm dry limb wood, interspersed together, with 120-200 litres of water (44 gallon drum) on the ready for the final soak.

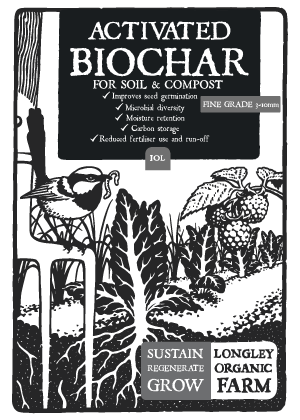

The biochar

The burn temperature typically ranges from 500C -700C ensuring the quality of the carbon platelets is maintained (not turned to ash) and pyrolising volitiles from resins. As more dry matter is placed on top, the conical shape starves oxygen the lower embers maintaining carbon platelet integrity, the final, post water drenched product is a very evenly processed charcoal with no ash, as higher temperatures are not reached. There is variation in the burning qualities of different timbers that you vary or experiment with, however the versatility of the cone leaves you with a quality soil/ carbon building product everytime.

Activation-inoculation

There are a number of techniques that can be employed to activate the char.

Adding to composts during formation - This will allow the biochar to house the developing bacteria and buffer excess heat during hot composting, also retaining humidity.

Soak with a chosen additive - there are many locally occuring raw materials you can use, both for to encourage microbes and a food source. Urine, effective microbes, seaweed solution, fish emulsion, whey powder ,wild yeasts and native microbes like a sourdough starter, fine rock dust.

You can spray the biochar with liquids to use quickly or you can leave it coated in goodies for months before you use it. You can soak it in microbes, seaweed etc and then drain overnight then use on your vegie beds.

Amounts for use

Depending on the job you can add quite a bit. We add 300-500ml/m2 to our vegie beds of fine grade (3-5mm) with our other soil amendments, we could add significantly more and can add the same again the following year.

One benefit we hope to gain from this is temperature buffering for the root systems as well as the microbes. It may be possible to pick leafy greens, beets etc later into the heat of the day if we have enough in the soil.

For fruit trees, blueberries etc you can add a good amount under the root ball prior to planting (1-3 litres), a wonderful thing to do for your plant and the soil and whoever consumes it!

Prices range depending on Australian/ New Zealand destination , $550-$700

To arrange a viewing and purchase of your cone kiln please contact us